The advantages of PET bottles in cosmetic packaging

Dec 17, 2024

PET bottles, also known as polyethylene terephthalate bottles, offer several advantages in cosmetic packaging:

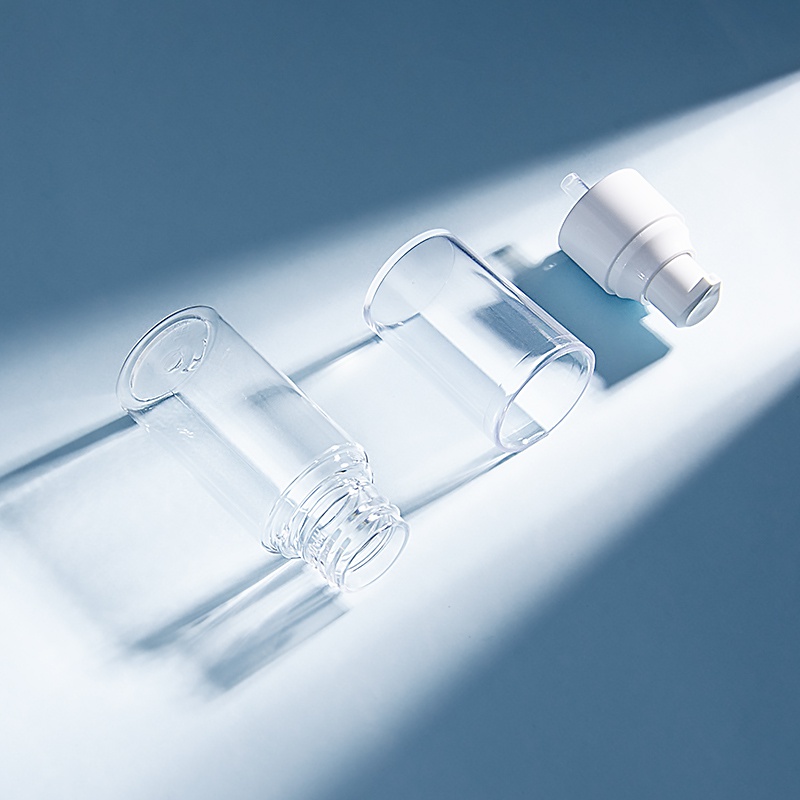

Transparency: PET bottles are transparent, allowing the product inside to be visible. This is particularly beneficial for cosmetic products that come in vibrant colors or have unique textures, as it enhances the visual appeal and allows customers to see the product before purchasing.

Lightweight: PET bottles are lightweight, making them convenient for both manufacturers and consumers. They are easy to handle, transport, and store, reducing shipping costs and improving overall usability.

Durability: PET bottles are known for their durability and resistance to breakage. They can withstand impact and rough handling, making them ideal for cosmetic products that may be subject to frequent use or travel.

Chemical Resistance: PET bottles have good chemical resistance, ensuring that the cosmetic product inside remains safe and unaffected. They can resist the potential interaction between the packaging material and the product, preserving its quality and efficacy.

Recyclability: PET bottles are highly recyclable. They can be collected, processed, and recycled into new products, reducing waste and environmental impact. The ability to recycle PET bottles aligns with the increasing demand for sustainable and eco-friendly packaging solutions in the cosmetic industry.

Versatility: PET bottles can be manufactured in various shapes and sizes, allowing for customization and versatility in cosmetic packaging. They can accommodate different closure mechanisms, such as pumps, sprayers, or flip-top caps, providing convenience and functionality to consumers.

Overall, the advantages of PET bottles in cosmetic packaging include transparency, lightweight design, durability, chemical resistance, recyclability, and versatility. These qualities make PET bottles a popular choice for a wide range of cosmetic products

Read More